Phase 1. Design and printing

This phase includes both the design of the die, the tool that gives the box its shape, and the graphic design, taking into account the brand identity and the customer’s requirements.

Phase 2. Preparation of paper and glue

Preparation of paper and glue Selection of paper: The type of paper suitable for the manufacture of the corrugated cardboard is chosen, taking into account factors such as the strength, quality and thickness required. Preparation of the glue: The glue or adhesive to be used to bind the different layers of paper during the process is prepared.

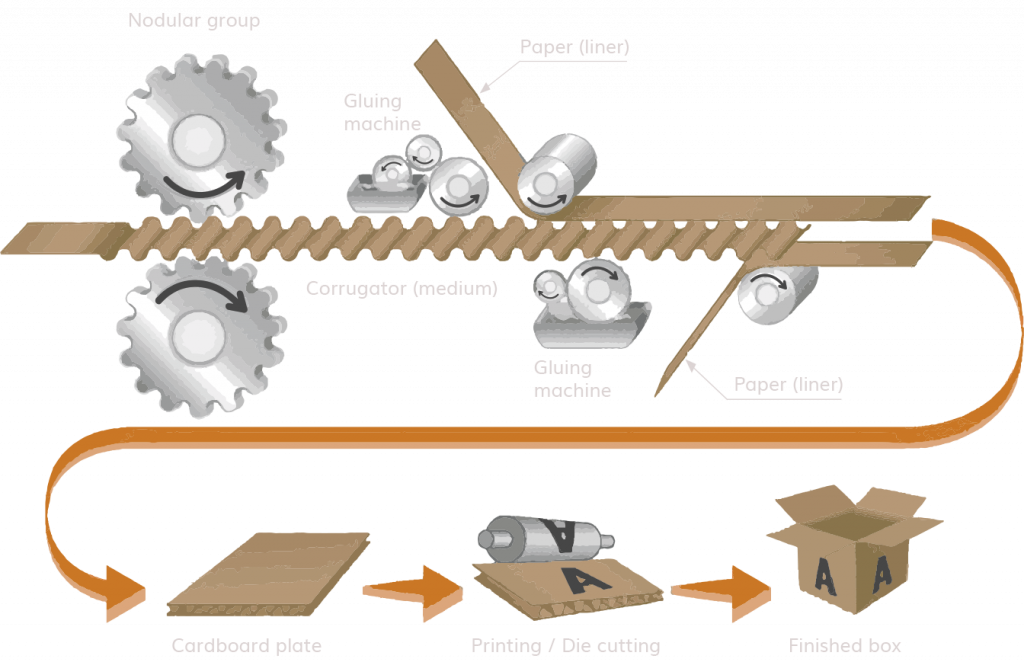

Phase 3. Corrugation

Corrugation In this phase the corrugator produces sheets of corrugated cardboard. Using rolls of paper, several layers are bound together to create the finished product. The characteristic shape of corrugated cardboard, also known as corrugation, is achieved through grooved rollers that apply heat and pressure to obtain its distinctive structure.

Phase 4: Printing and Die-Cutting

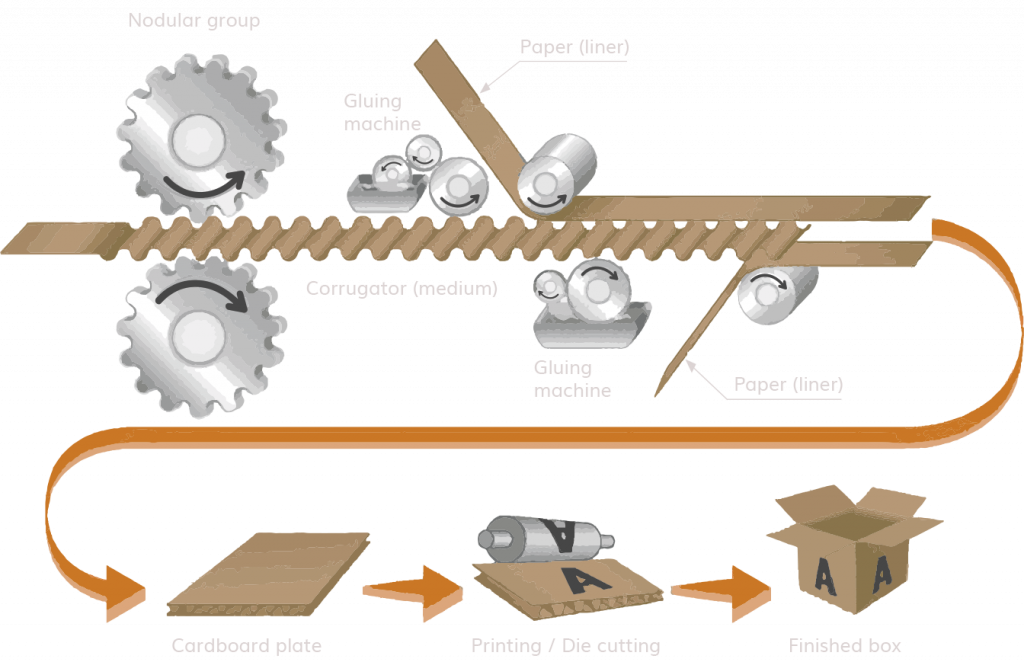

Converting Route.

Die-Cutters and Casemakers

Die-Cutters and Casemakers printing: During this stage, the process of printing text and images with the information required by the customer is carried out.

Die-Cutting: this process, with the help of a tool called a die, shapes the corrugated cardboard according to the previously defined design.

Glued/folded Only Casemaker route boxes are glued and folded before reaching the customer, ready for use upon reaching the customer.

Phase 5 Packaging and Storage

The corrugated cardboard boxes are suitably packaged and stored, ready for distribution and use.

Recycled fibre paper is obtained from the recycling of used paper and cardboard.

Virgin fibre paper is produced from pulp obtained directly from trees and has not previously been used in the manufacture of paper.

In the warehouse, packaging and finished products occupy a crucial place. This space is strategically designed to ensure their protection and organisation, ensuring that they are ready for shipping or distribution.

The storage of containers or finished products is carried out in an orderly and efficient manner. Shelving or palletising systems are used that allow items to be stacked and sorted safely, optimising the available space.

In addition, inventory management techniques are applied to maintain accurate stock control. Barcodes, tracking systems and specialised software are used to record and monitor the quantity and location of each packaging or finished product.

The correct storage of packaging or finished products not only ensures their safety, but also facilitates their quick and efficient access when required for distribution.

With an area of 7,300 m², our warehouse offers a spacious and strategically designed environment. This allows us to optimally manage our 4,600 pallets and store up to 4,100,000 boxes.

Recycled fibre paper is obtained from the recycling of used paper and cardboard.

Characteristics:

Sustainability: the reduction of waste and the use of natural resources. By using recycled paper, forestry conservation is promoted and the demand for virgin pulp is decreased.

Lower environmental impact: the production of recycled paper generates a lower environmental footprint compared to virgin fibre paper, as it requires less energy and water during its manufacturing process.

Variable quality: The quality of recycled fibre paper may vary depending on the recycling process and the composition of the fibres used. Sometimes, it may have lower resistance and rigidity compared to virgin fibre paper.

Texture and Appearance: It may have a rougher texture and a slightly different appearance compared to virgin paper. This is due to the mixture of different types of recycled paper.

Virgin fibre paper is produced from pulp obtained directly from trees and has not previously been used in the manufacture of paper.

Characteristics:

Strength and durability: Virgin fibre paper tends to be stronger and more durable compared to recycled paper. This makes it suitable for applications that require greater rigidity and protection, such as the packaging of heavy or delicate products.

Appearance and whiteness: Virgin fibre paper usually has a more uniform appearance and greater whiteness compared to recycled paper. This makes it a preferred option for those cases where a more aesthetic presentation or a higher quality printing is desired.

Processing and handling: Due to its greater strength, virgin fibre paper may be easier to handle and process in certain cases, such as in the manufacture of boxes with more complex designs or shapes.

It is important to note that both recycled fibre paper and virgin fibre paper can have suitable applications in different contexts, and the choice will depend on the specific requirements of each product, environmental considerations and the manufacturer’s preferences. . It should be noted that both types of paper are recyclable, regardless of which type.